There is a paradigm shift happening to the energy hub in the Northern Panhandle within the Ohio River Valley with the announcement of the Shell Petrochemical Plant and subsequent announcement of second plant in Ohio. While petrochemical manufacturing began in Appalachia in the 1920’s, the Gulf Coast region has been the center of the U.S. petrochemical industry since the mid20th century. With its abundant supplies of hydrocarbon raw materials and vast network of pipelines and natural gas liquids storage structures, it has been the center of chemicals production for the last six decades. Much of the industry’s recent wave of shale-related investment was destined for Texas and Louisiana, with numerous projects completed, planned, or underway.

There is a paradigm shift happening to the energy hub in the Northern Panhandle within the Ohio River Valley with the announcement of the Shell Petrochemical Plant and subsequent announcement of second plant in Ohio. While petrochemical manufacturing began in Appalachia in the 1920’s, the Gulf Coast region has been the center of the U.S. petrochemical industry since the mid20th century. With its abundant supplies of hydrocarbon raw materials and vast network of pipelines and natural gas liquids storage structures, it has been the center of chemicals production for the last six decades. Much of the industry’s recent wave of shale-related investment was destined for Texas and Louisiana, with numerous projects completed, planned, or underway.

However…. this is changing. Announcements of significant petrochemical industry investments in our region have been made, with several projects already in process. The Appalachian region in general, and the Ohio River Valley in particular, is the ideal location for the second major petrochemical manufacturing hub in the United States, offering:

- Proximity to abundant NGL resources from the shale formations.

- Proximity to manufacturing markets in the Midwest and along much of the East Coast.

- Opportunity to strengthen the U.S. economy by providing employment and supply diversity.

The Weirton-Steubenville Metropolitan Area consists of Brooke and Hancock counties in the Northern Panhandle of West Virginia and Jefferson County in Ohio. Brook and Hancock counties have experienced millions of investment dollars over the past eight years reaching outward from Weirton to Chester in the north and Beech Bottom in the south. The investment dollars have spanned across manufacturing, transportation, health care and retail business sectors. These types of businesses will support the growth of the energy hub in the region.

The industry clusters of energy/shale, value-added metals, chemicals, transportation logistics, and health care have grown organically and continue to attract investments. These industry clusters are employing over 8,000 people.

The industry clusters of energy/shale, value-added metals, chemicals, transportation logistics, and health care have grown organically and continue to attract investments. These industry clusters are employing over 8,000 people.

The investment in the Panhandle region goes beyond brick and mortar, but also to support workforce development through nationally acclaimed training programs in job search training, retaining and retooling a workforce to support and supply the necessary pipeline of labor needed for expansion. Weirton-Steubenville area is 3rd in nation in construction growth. For consecutive years the tri-county area has ranked among highest in nation in increase in construction jobs. The result – West Virginia has the nation’s second lowest overall employee turnover rate.

We are excited about the business growth and employment opportunities in Weirton-Steubenville Metropolitan Area and stand ready to meet future demands through investment in our infrastructure, training and the people that live, play and work in the Northern Panhandle.

Experience the Power of a Community and find out more about opportunities within the Northern Panhandle.

The Rebirth of the Northern Panhandle article provided by Patrick Ford, Executive Director BDC of the Northern Panhandle.

About CAVCON: CAVCON brings together three generations of Building Owners/Managers and General Contractors with Design/Build expertise focusing on Medical, Commercial, Retail, Manufacturing and Light Industrial projects. As a full-service merit shop general construction company CAVCON provides design-build services incorporating value engineering, collaborative modeling and turn-key general construction services to deliver the best outcomes for our clients.

As the Mon Valley looks to remake itself, it must deal with the blight evident in its communities. Many communities saw a steep decline in tax revenue and as such were not able to keep up with buildings that were erected many years ago and have since fallen into decline.

As the Mon Valley looks to remake itself, it must deal with the blight evident in its communities. Many communities saw a steep decline in tax revenue and as such were not able to keep up with buildings that were erected many years ago and have since fallen into decline.

What if you knew your building project timeline could be cut in half, your costs for construction were less, and you were able to open for business sooner with incoming revenue? To top it all off, sustainability and LEED were incorporated into the project.

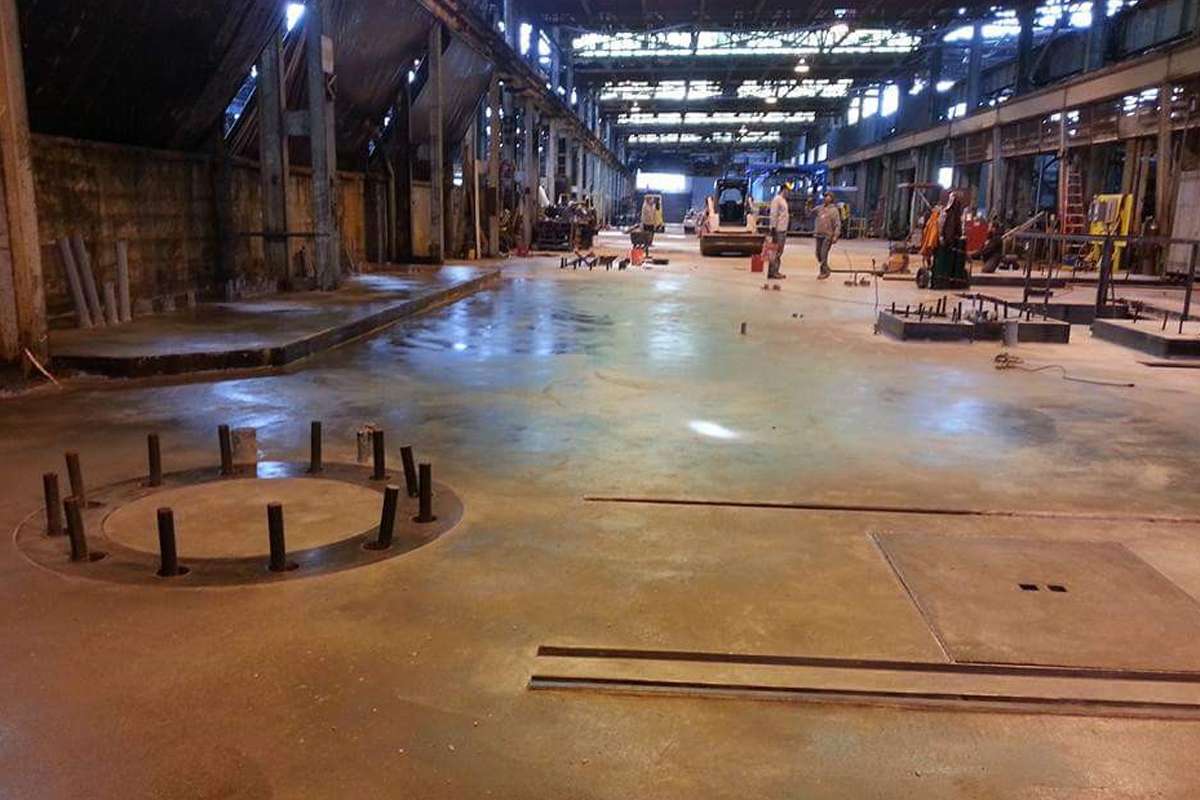

What if you knew your building project timeline could be cut in half, your costs for construction were less, and you were able to open for business sooner with incoming revenue? To top it all off, sustainability and LEED were incorporated into the project. As Beaver and surrounding counties prepare for the influx of work staff and ancillary services needed, consider how a blend of repurposing older structures, along with conventional new construction and modular construction will help to maintain the integrity of our local communities and infrastructure needed to support this project, as well as save time to provide a quick turnaround for services.

As Beaver and surrounding counties prepare for the influx of work staff and ancillary services needed, consider how a blend of repurposing older structures, along with conventional new construction and modular construction will help to maintain the integrity of our local communities and infrastructure needed to support this project, as well as save time to provide a quick turnaround for services.

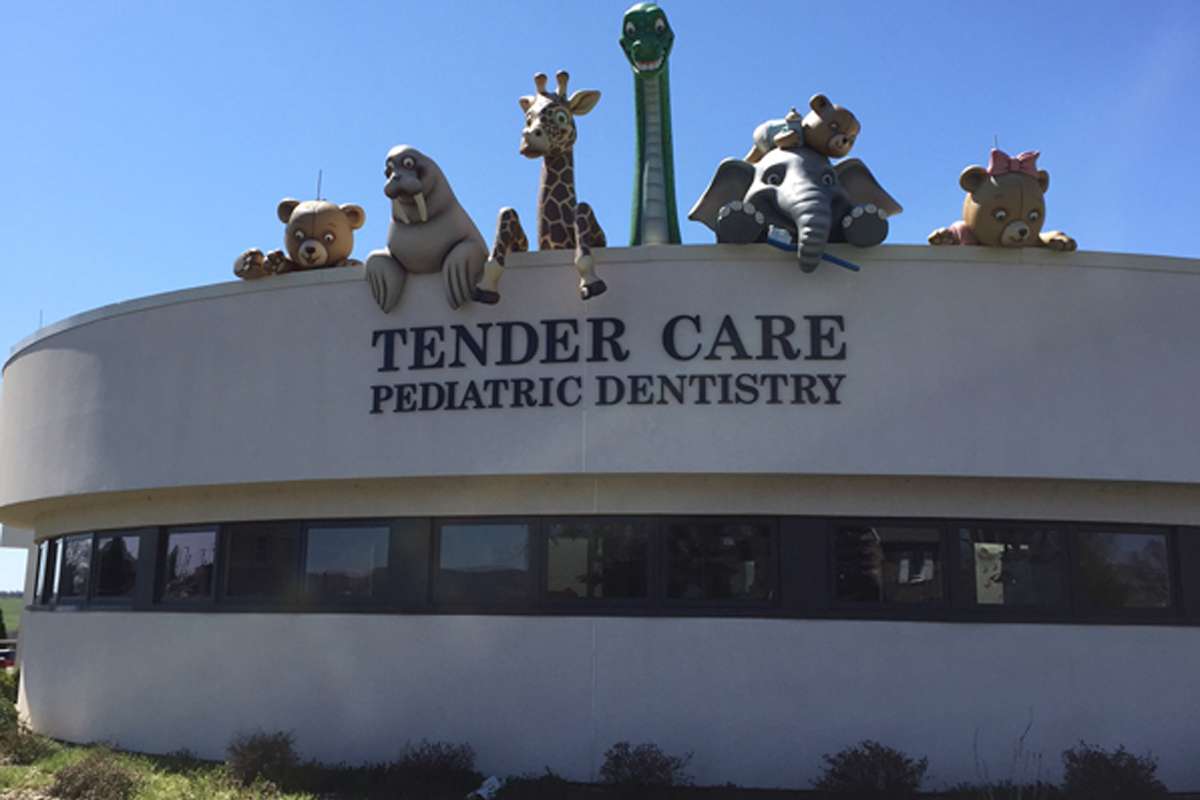

You may wonder what this has to do with construction. A customized project such as this is about understanding who your audience is and creating an environment and place where they can feel comfortable.

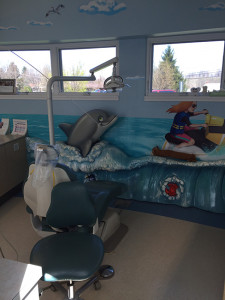

You may wonder what this has to do with construction. A customized project such as this is about understanding who your audience is and creating an environment and place where they can feel comfortable. When building for a younger audience, there were plenty of things we kept in mind. Pediatric healthcare facilities are distinctive for their age adaptive design, detailing that engages a child’s imagination and a child-scaled environment.

When building for a younger audience, there were plenty of things we kept in mind. Pediatric healthcare facilities are distinctive for their age adaptive design, detailing that engages a child’s imagination and a child-scaled environment. When you think about your audience and your customers, are you updating dated facilities, adding amenities to waiting areas, creating a comfortable space for children to play, and tailoring your facility toward customer needs and wants? If a customer feels comfortable, they will want to come back for more. If employees enjoy their work environment, they will be more productive.

When you think about your audience and your customers, are you updating dated facilities, adding amenities to waiting areas, creating a comfortable space for children to play, and tailoring your facility toward customer needs and wants? If a customer feels comfortable, they will want to come back for more. If employees enjoy their work environment, they will be more productive.